Excavator Buckets

Industry standard quality

Our Bucket list

SEAYON buckets are manufactured as per the set industry standards and norms using standard quality raw materials

Our Brands of Buckets

SEAYON buckets are manufactured as per the set industry standards and norms using standard quality raw materials

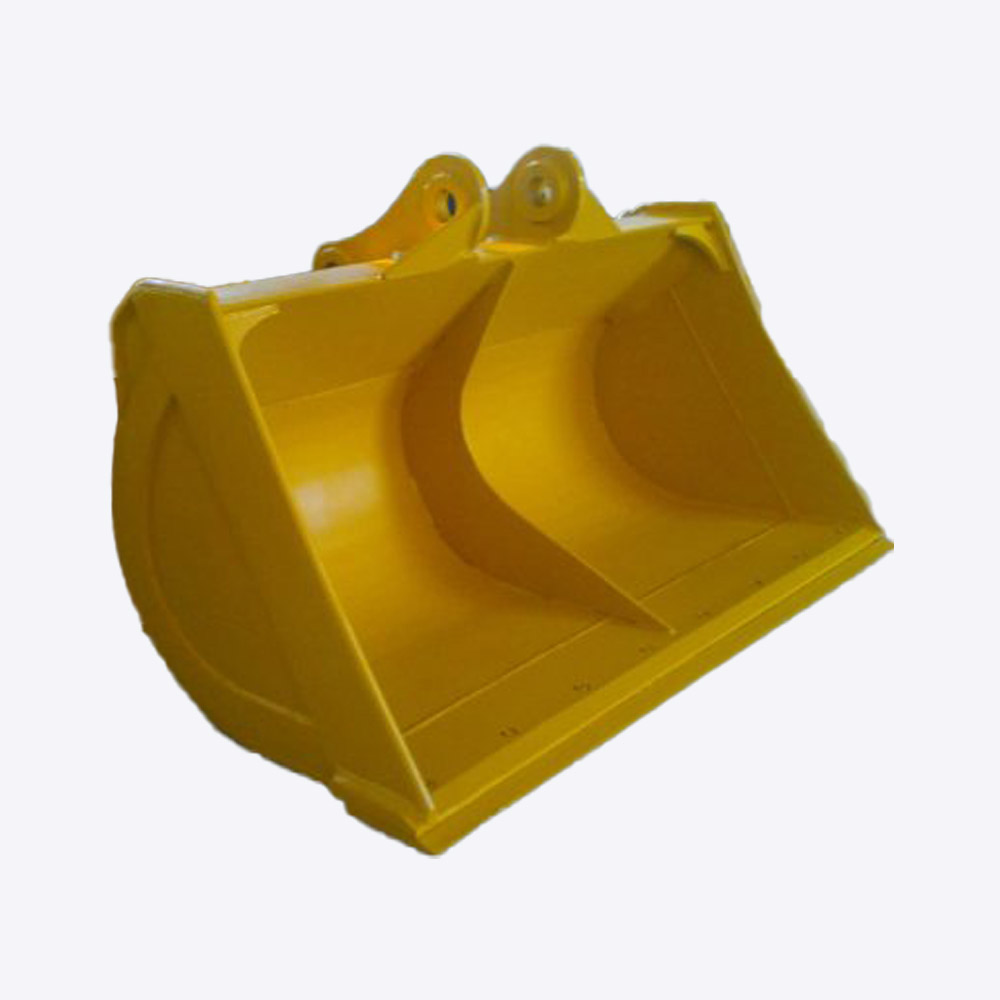

Shovel Bucket

Features

- HARXOX lip with center shrouds system for more efficient production and superior reliability

- One-piece hinge neck for a smooth, low-stress transition from the hinge body to dump cylinder lugs

- 65 Rockwell hardfacing and Chromium wear plate provide maximum protection and resistance to wear out

Features

- KOMATSU PC1250

- TATA HITACHI EX1200

- BEML 1000

- KOMATSU PC800

- TATA HITACHI EX400

Backhoe Bucket

Features

- HARDOX CUTTING EDGE USED IN BUCKET AS PER DRAWING REQUIREMENT

- 65 ROCKWELL HARDFACING PROTECT THE BASE MATERIAL

- STEEL BAR ROUND ON SAFETY FOR SITE SAFETY

- CENTER SHROUDS BETWEEN ADOPTERS

- WELDED SIDE CUTTERS

- T STRIPS IN BUCKET

- WEAR PLATES

Features

We are leading excavator backhoe buckets manufacturer in india with 300 types of Drawings of buckets. You just need to give us Model no. of the following machine

- JCB 2DX

- JCB 3DX

- JCB JS81

- JCB JS120

- JCB JS 140

- JCB JS 200

- JCB JS 205

- JCB JS 215

- JCB JS220

- JCB JS 305

- JCB JS 380

- KOMATSU PC 71

- KOMATSU PC130

- KOMATSU PC 200

- KOMATSU PC 210

- KOMATSU PC 300

- KOMATSU PC350

- KOMATSU PC400

- KOMATSU PC450

- KOMATSU PC600

- KOMATSU PC800

- KOMATSU PC 1250

- KOMATSU PC 2000

- TATA JD315

- TATA HITACHI EX 70

- TATA HITACHI ZAXIS 80

- TATA HITACHI EX 110

- TATA HITACHI ZAXIS 140

- TATA HITACHI EX 200

- TATA HITACHI EX 210

- TATA HITACHI ZAXIS 220

- TATA HITACHI EX350

- TATA HITACHI ZAXIS 370

- TATA HITACHI ZAXIS 400

- TATA HITACHI ZAXIS 470

- TATA HITACHI ZAXIS 650

- TATA HITACHI ZAXIS 870

- TATA HITACHI EX1200

- KOBELCO SK 140

- KOBELCO SK 210

- KOBELCO SK 220

- KOBELCO SK 350

- KOBELCO SK 380

- KOBELCO SK 480

- KOBELCO SK 500

- KOBELCO SK 850

- SANY SY 140

- SANY SY 205

- SANY SY 210

- SANY SY 215

- SANY SY 220

- SANY SY 235

- SANY SY 240

- SANY SY 245

- SANY SY 265

- SANY SY 305

- SANY SY 335

- SANY SY 365

- SANY SY 500

- SANY SY 700

- SANY SY 750

- HYUNDAI ROLEX 110

- HYUNDAI ROLEX 140

- HYUNDAI ROLEX 210

- HYUNDAI ROLEX 215

- HYUNDAI ROLEX 220

- HYUNDAI ROLEX 230

- HYUNDAI ROLEX 245

- HYUNDAI ROLEX 340

- HYUNDAI ROLEX 390

- HYUNDAI ROLEX 510

- HYUNDAI ROLEX 800

- HYUNDAI ROLEX 1200

- VOLVO EC 140

- VOLVO EC 200

- VOLVO EC 210

- VOLVO EC 220

- VOLVO EC 250

- VOLVO EC 290

- VOLVO EC 300

- VOLVO EC 350

- VOLVO EC 380

- VOLVO EC 480

- VOLVO EC 750

- VOLVO EC 950

- DOOSAN DX 140

- DOOSAN DX225

- DOOSAN DX 235

- DOOSAN DX 255

- DOOSAN DX 300

- DOOSAN DX 360

- CAT 424

- CAT 320D

- CAT 329

- CAT 330

- CAT 336

- CAT 349

- CAT 374

- CAT 390

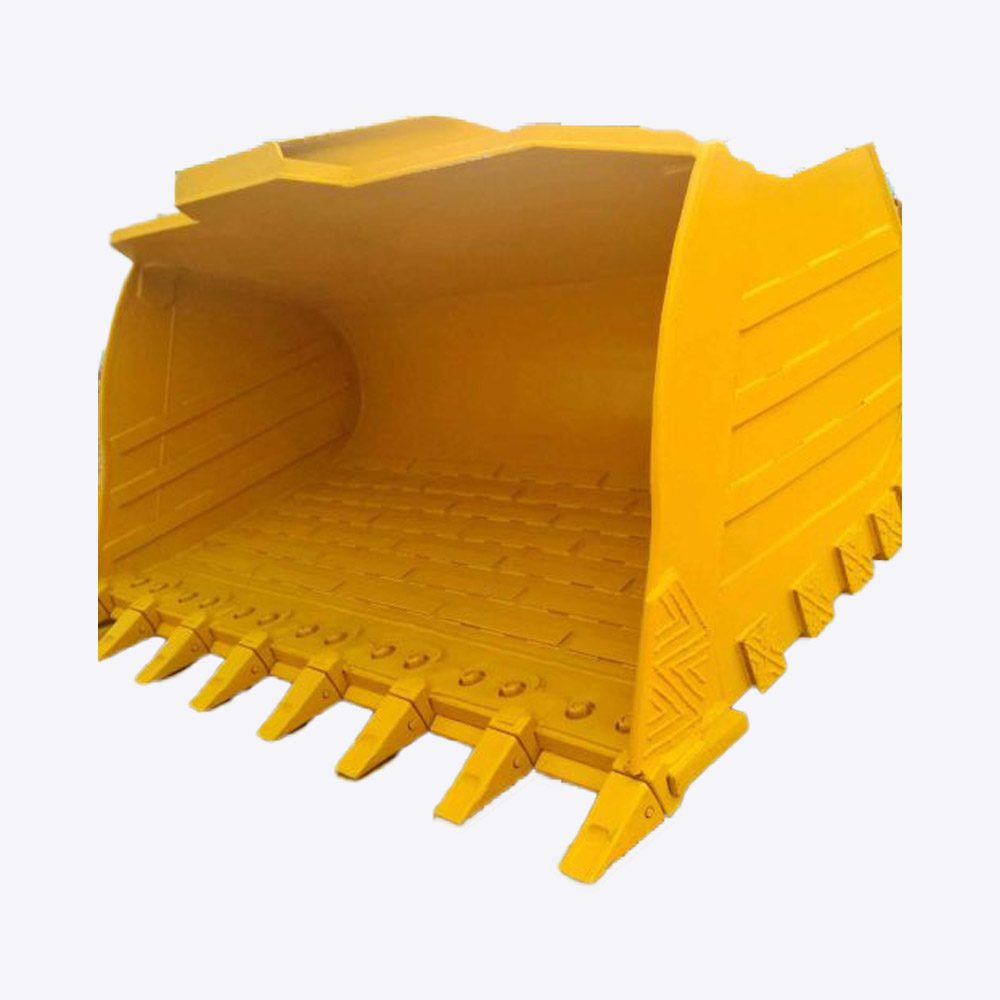

Loader Bucket

Features

SAEON Loader Buckets handle specific materials such as coal, woodchips, mulch, hot slag, rocks, or shredded scrap. SAEYON offers more special application buckets than any other allied equipment manufacturer.

Load Haul Dump Bucket

All type of LHD Bucket Manufacturer

- Sandvik Lh307

- Sandvik Lh410

- Sandvik Lh 517

- Atlas Capco ST 1030

- Emco Elecon

Block Handling Bucket

Features

- he Block bucket is suited to handle and position rocks and blocks.

- Recommended also for block and rocky embankments.

- This bucket is particularly strong and resistant to shocks and wear thanks to the bottom, sideblades and sidewall reinforcements in HARDOX®450 and rear wear protections in HARDOX®500.

- Fitted with HARDOX®450 front blade with standard tip adpter-systems and rear tooth in HARDOX®450 to allow blocks adjustment.

- ROCKS AND BLOCKS HANDLING APPLICATION

- REINFORCED WITH HARDOX 450/500

- REAR TOOTH IN HARDOX 450 FOR BLOCK ADJUSTMENT

- FITTED WITH STANDARD TIP-ADAPTER SYSTEM

- AVAILABLE FOR ALL EXCAVATORS AND QUICK COUPLER MODELS

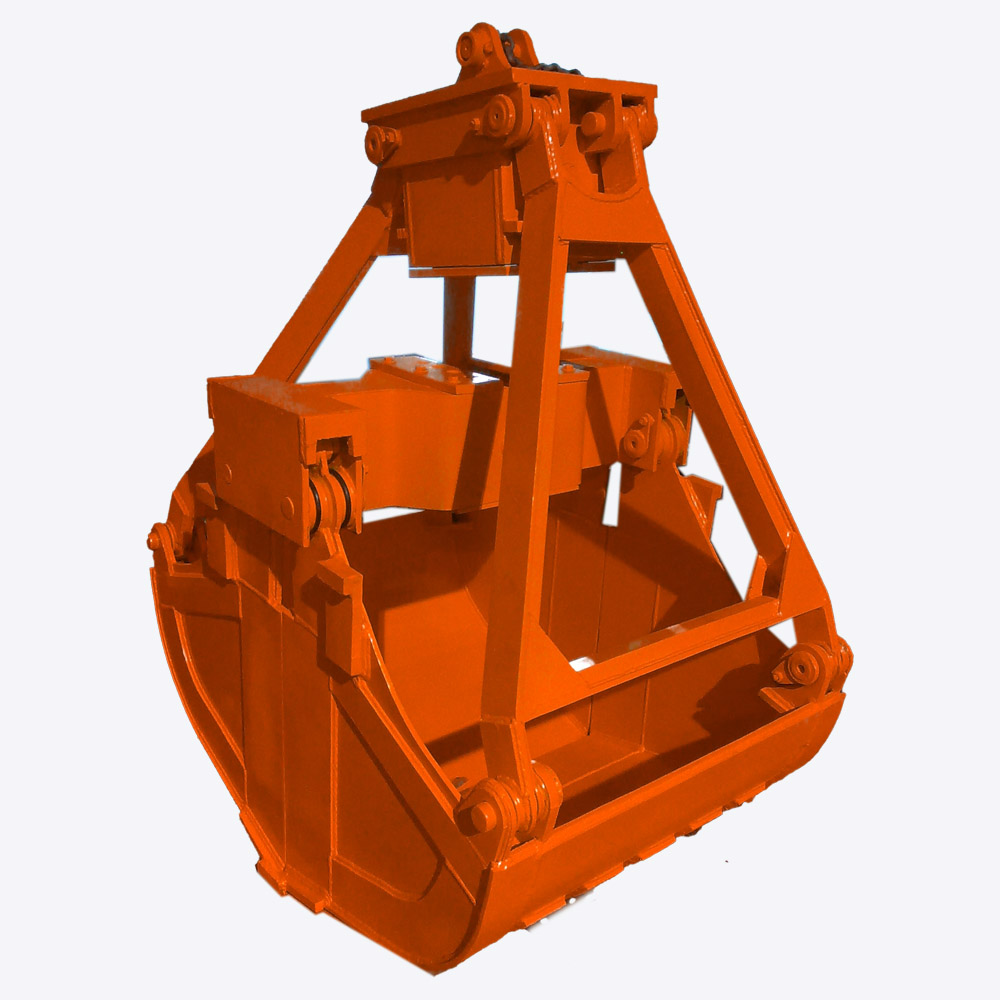

Clamshell Bucket

Hydraulic Clamshell

The hydraulic clamshell bucket is designed to be attached onto an excavator. The Single or quad hydraulic cylinders/rams mounted on the outer rim of the bucket provide excellent digging force. The inner side of the bucket has a smooth surface for easy unloading of high viscosity material such as mud and clay, while the outer layer is reinforced with additional layer of wear strips. The bowl’s radius has been optimized to match with the locus of the hydraulic cylinder/ram to deliver consistently full load for maximum productivity.

Hydraulic designs are meant for attaching to an excavator while the mechanical cable operated are designed to work with a broad range of cranes. The buckets are constructed with high tensile steel and wear resistant steel with capacity starting from 1 cubic meter and upwards.

Mechanical/Cable Clamshell

The fully mechanical clamshell is designed specifically to be used on a crane for large capacity dredging and digging applications. The opening and closing action is operated via cable. The inner side of the bucket has a smooth surface for easy unloading of high viscosity material such as mud and clay, while the outer layer is reinforced with additional layer of wear strips. The hanger is constructed with high tensile steel.

The design concept and criteria of a dredging versus a general purpose loading/unloading mechanical/cable clamshell differs greatly due to its differences in the nature of application and working condition. The geometry and weight distribution of a good clamshell design play a significant role in determining its overall efficiency.

Ripper Tooth

Features

SAEYON ripper tooth is designed for the detachment of blocks.The specialized material used guarantees extended life for the attachments.

SAEYON manufactures ripper tooth for excavators starting from the 20-tonne class to upward

Build and Applied to

The ripper tooth is made of very high resistant structural steel.

All the materials used are compliant with the current regulations and have a valid production certificate.

- Front END Tooth Point

- Front END Solid

Skeleton Bucket

Features

- Great for shifting out rocks in soil, effectively mining and sorting rock, and removing other debris without the soil.

- Available in many different sizes, widths, and even custom rib spacing configurations.

Reclaimer Bucket

- It is mainly composed of steel structure, jib belt conveyor, feeder tripper, luff mechanism, slew mechanism, travel mechanism, spray system, wheel bucket device, electrical system, necessary safety related components and accessory devices. The jib of stacker and reclaimercould slew, luff, prolong and shorten itself. And end turning bucket is material grab device.

- Types of stacker reclaimer: Stacker, wheel bucket reclaimer and wheel bucket stacker and reclaimer.

Features

- Enhanced performance

- Longer life

- Less maintenance

- Flawless design

Piling Bucket

PILING buckets are used for drilling in cohesive and non-cohesive soil below groundwater level. PILING buckets are suitable for breaking and ripping hard soil up to medium hard rock. Digga Drilling Buckets boast a heavy duty construction.Its design allows for a manual hand-operated, or automatic opening mechanism to be fitted (for emptying)- For drill rigs fitted with striker plate.

- Heavy duty construction with provision for reamer bars

- Opening mechanism options include manual hand-operated or fully automatic (suits drill rigs with striker plate fitted)

- Base options include swivel and valve style

- Specialised buckets including rock and earth available

- Other tooth options available upon request

Ditch/Trench Bucket

- High Performance

- Reliability and Durability

- Versatility and Convenience with Couplers